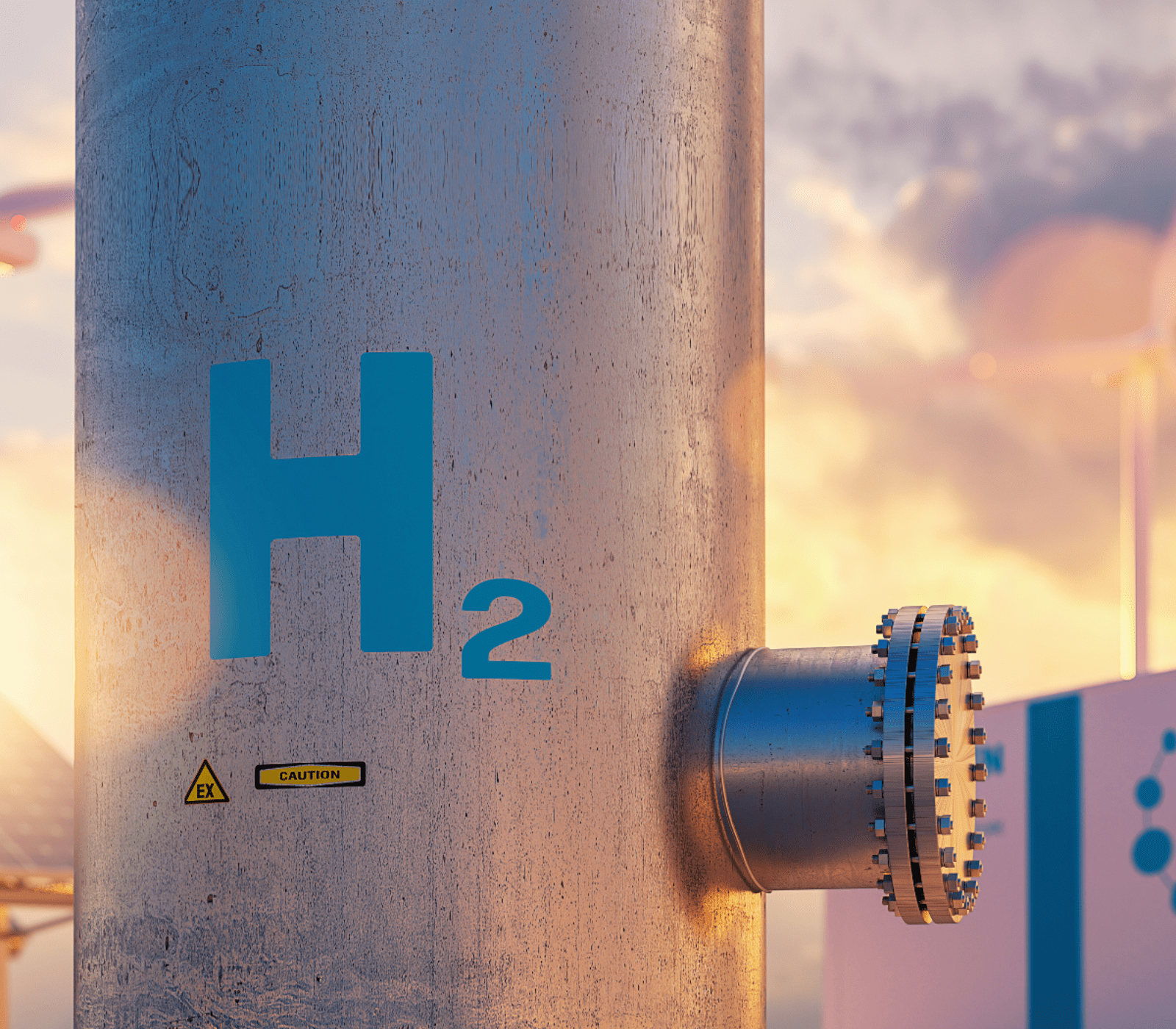

Material Selection Expertise for Hydrogen Production

Confidential

Confidential

BACKGROUND

An innovative research and development company in the field of sustainable hydrogen required our support to enable a pioneering scale-up engineering initiative focusing on the validation and optimisation of a fixed bed chemical looping process for hydrogen production. This groundbreaking project revolves around the conversion of air, nitrogen, steam, and blast furnace gas into hydrogen, with nitrogen and carbon dioxide serving as crucial byproducts for integrated processes. The innovative design aims to optimise the production of hydrogen as a clean energy source while effectively utilising nitrogen and carbon dioxide for additional industrial applications. The complex nature of the project necessitated specialised materials support, without which the project could not proceed, and they required quick answers to provide useful inputs for their feasibility study.

THE CHALLENGE

The scale-up engineering project mandated a comprehensive approach to materials selection, considering a range of potential damage mechanisms, including 475°C embrittlement, boiler water and steam condensate corrosion, high-temperature hydrogen attack, and thermal fatigue. This intricate challenge demanded a meticulous evaluation of materials to ensure optimal performance and integrity within the rigorous operational environment of the fixed bed chemical looping system.

OGC ENERGY’S ROLE

In response to the multifaceted challenge, our team at OGC Energy undertook a comprehensive assessment of the project's heat and material balance (HMB) and process flow diagrams (PFD) to facilitate a robust materials selection process. Our expertise enabled the identification of suitable materials best suited for Class 5 Estimate Purposes, considering the specific requirements of the project. By meticulously addressing the various potential damage mechanisms, we provided our client with a comprehensive list of applicable materials, accompanied by a final recommendation that aligns with the project's cost, long-term sustainability and operational efficiency goals.

HOW WE HELP YOU

OGC Energy’s extensive knowledge and experience ensure that your project is fully equipped for a sustainable future. They're committed to creating solutions for materials selection to underpin your success. Discover how OGC Energy can assist your project by providing comprehensive solutions in materials and corrosion and take the next step in the field of hydrogen production.

Reduce risk with our expert advice - Contact us now