Recent Safety Alerts from BSEE

Recent Safety Alerts from the Bureau of Safety and Environmental Enforcement

Two recent safety alerts have been issued by the Bureau of Safety and Environmental Enforcement,

- Connector and Bolt Failures

- Chemical Injection Point Corrosion Causes Production Header Failure

In February a safety alert informed the industry of the recurring problem of connector and bolt failures in various components used in risers and subsea blowout preventers used in offshore operations. These failures are of great concern to BSEE due to their frequency and the potential for a catastrophic event. Further work from the BSEE in collaboration with industry bodies such as API have resulted in guidance for bolting, from this work the following actions have been proposed for future collaboration:

- Defined “critical bolting” as bolting that the failure of which could result in loss of containment of wellbore fluids to the environment

- Voluntary industry adoption of API 20 E/F for critical BOP bolting

- Voluntary industry upgrade of critical bolting with hardness > 35 HRC

- Enhanced QAQC of 3rd party manufactured bolting (i.e., sampling, 20 E/F requirements)

- Updated make-up procedures, with additional engineering rigor and oversight

- Elimination of electroplated Zinc coatings

- Enhanced failure reporting with wider distribution

- Consistent with the direction of API standards work

If you want to get more information on BSEE alerts on bolts follow the link: www.bsee.gov/bolts/

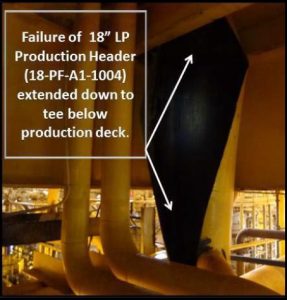

Also, a recent failure in a 18-in low pressure production header on a producing platform in the Gulf of Mexico failed under normal working pressure. The failure ruptured the header, opening a 10-ft long split and releasing production fluids at a pressure of 250-psi. An investigation concluded the failure was caused by a corrosive loss of pipe integrity immediately beneath a chemical drip injection point used to introduce an acidic demulsifier into the flow stream. Over time the demulsifier corroded away approximately 50-percent of the metal thickness of the pipe below the injection point. Operators are encouraged to develop procedures ensuring the proper use, installation, and verification of chemical injection equipment.

For further information you can download the BSEE alert: